Synopsis: Jain Resource Recycling is emerging as a strong copper recycling player backed by global sourcing, diversified products and forward integration into value-added copper segments. With robust revenue growth, expanding margins and policy support for recycled metals, management expects 40 to 50 percent growth in FY27, positioning it for scalable long-term expansion.

India’s push toward energy transition, electric mobility and domestic manufacturing is sharply increasing demand for recycled copper, a metal critical to power grids, EVs, renewables and industrial infrastructure. With global supply constraints, rising copper prices and policy mandates encouraging higher recycled content, organized recyclers with scale, global sourcing and forward integration plans are well placed to benefit.

Add to this an aggressive expansion into value-added copper products and management guiding for 40 to 50 percent revenue growth in FY27, and the stage appears set for a potential high-growth recycling story.

About Jain Resource Recycling

Jain Resource Recycling Limited was incorporated in 2022 and operates in the recycling and manufacturing of non-ferrous metal products. The company produces lead and lead alloy ingots, copper and copper ingots, as well as aluminium and aluminium alloys. Through this diversified product range, it caters to multiple industrial applications that rely on recycled metals.The stock has corrected from its peak of Rs. 461 in November 2025 and is currently trading at Rs 378.80. Jain Resource Recycling currently has a market capitalization of Rs. 13,061.50 crore.

What Does The Company Do?

Core Business and Revenue Mix

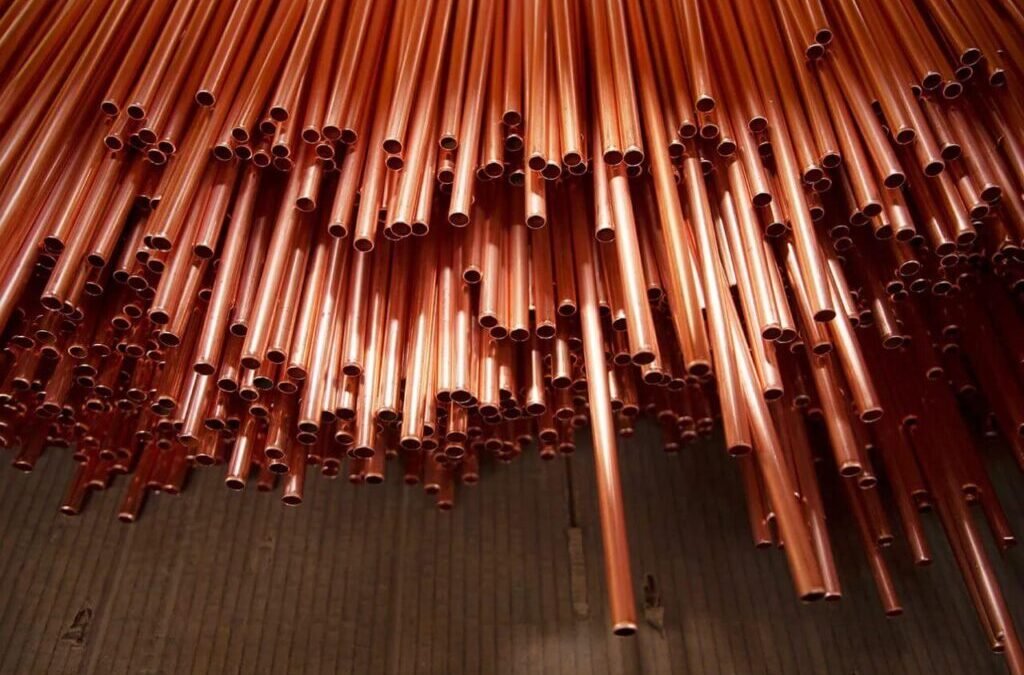

Jain Resource Recycling is mainly engaged in manufacturing non-ferrous metal products through the recycling of metal scrap. Its key products include lead and lead alloy ingots, copper and copper ingots, and aluminium and aluminium alloys. The company also undertakes trading of non-ferrous metals and other commodities as part of its operations.

Its lead ingot brand is registered with the London Metal Exchange, which allows the company to access a wider global customer base. This registration ensures that its products meet international quality standards and enables it to supply products with LME reference pricing in global markets. In terms of revenue contribution (9MFY26), copper and copper alloy products account for around 52 percent of total revenue, while lead and lead alloy ingots contribute about 43 percent. Aluminium and aluminium products represent nearly 4 percent.

Diversified Product Capability

The company has developed a wide product range across lead, copper, aluminium, plastics and tin, catering to multiple end-use industries. In lead, it manufactures refined lead ingots produced from scrap, with purity levels ranging from 99.97 percent to 99.99 percent. These are mainly used in lead-acid batteries, radiation shielding, ammunition, aerospace and related sectors. It also produces antimony lead ingots used in battery terminals, anodes, cathodes and grid paste, as well as remelted lead ingots serving the battery, cable and electrical industries.

In copper, the company offers refined copper billets with purity levels between 95 percent and 99.07 percent, used in cables, chemicals and automotive applications. It also manufactures copper alloy billets and ingots by combining copper with metals such as zinc, tin or nickel for industrial use. In addition, it produces solid copper ingots with different purity levels and supplies finished copper scrap to meet recycled industrial demand.

Beyond lead and copper, the company operates in aluminium, plastics and tin. It manufactures aluminium alloy ingots in primary grades such as XSB and LM6 and secondary alloys like ADC-12, which are widely used in electrical, power infrastructure and electronics industries. It also supplies molten aluminium alloy directly to industries through its recycling process.

In plastics, scrap from lead batteries is recycled into PP/PVC granules used in pipes, cables and apparel manufacturing. Tin extracted as a by-product from the lead recycling process is used in electronics soldering, food packaging through tin plating and automotive components. As per the 9M FY26 mix, lead and lead alloy ingots contribute 52 percent, copper and copper ingots account for 43 percent, aluminium and aluminium alloys form 4 percent, and the remaining 1 percent comes from trading, service income and adjustments.

Sourcing Strength and Procurement Network

Jain Resource Recycling has built strong and diversified sourcing capabilities supported by a global procurement network spread across more than 120 countries. As of 9M FY26, 56 percent of its raw material sourcing is through imports, while 44 percent is sourced domestically, maintaining a balanced mix.

Within imports, the United States contributes 33 percent, the Dominican Republic 13 percent, Malaysia 6 percent, Brazil 5 percent, Kuwait 4 percent and other countries 40 percent. The company works with over 400 suppliers as of December 31, 2025, ensuring multiple sourcing options and reducing dependency risks. Around 69 percent of its import purchases are sourced directly from scrap yards, which improves cost efficiency and supply visibility. Supplier concentration remains moderate, with the top five suppliers accounting for 41 percent of raw material costs and the top ten contributing 48 percent.

Global Footprint and Client Portfolio

Jain Resource Recycling has established a strong global footprint supported by a diversified customer base and steady export presence. The company exports to more than 20 countries and derives 70 percent of its revenue from exports, while the remaining 30 percent comes from the domestic market as per 9MFY26 data. Its country-wise revenue mix highlights India contributing 30 percent, China 28 percent, Singapore 32 percent, South Korea 3 percent and others 7 percent. The company caters to a wide range of end-use sectors including electrical equipment, automotive industry, chemicals, aerospace and related industrial segments, reflecting the versatility of its recycled metal portfolio.

The company serves over 300 customers and maintains a high customer retention rate, with around 88 percent of its revenue generated from repeat customers as of December 31, 2025. This indicates long-standing relationships and consistent product quality across geographies. Despite a broad international presence, revenue concentration remains moderate, with the top five customers accounting for 46.9 percent of total revenue and the top ten customers contributing 58.5 percent. Overall, Jain Resource Recycling’s balanced domestic and export mix, diversified country exposure and stable customer relationships underline the strength and sustainability of its global operations.

Financials

Quarterly Performance, Annual Performance & TTM Performance

On a year-on-year basis, the company reported revenue of Rs. 2,775 crore in Q3 FY26. Sales growth remained strong and in double digits in both Q2 FY26 and Q3 FY26, ranging between 52 percent and 56 percent. Operating margins during 9M FY26 stayed in the range of 6 percent to 8 percent. Profit growth was even stronger. Q2 FY26 recorded a 78 percent increase in profit year on year, while Q3 FY26 saw profit rise sharply by 150 percent compared to the same quarter last year.

On an annual basis, the company has delivered double-digit growth for the last two financial years. In FY24, sales grew by 45 percent and net profit increased by 69 percent. In FY25, revenue rose by 61 percent while net profit grew by 44 percent. For FY25, total revenue stood at Rs. 7,126 crore and net profit came in at Rs. 223 crore. Operating margins remained steady at 5 percent, unchanged from FY24. Management has indicated that new value-added products are expected to improve EBITDA margins by around 2 percent in FY27.

On a trailing twelve-month basis, revenue stands at Rs. 8,198 crore and net profit at Rs. 334 crore. Operating margins have expanded to 7 percent, showing improvement compared to earlier levels.

Balance Sheet and Working Capital

Debt has increased sharply from Rs. 928 crore in March 2025 to Rs. 1,294 crore in September 2025. This rise is mainly due to higher copper prices and increased working capital requirements. After the IPO, management had guided that debt would be reduced to Rs. 500 crore, but it currently remains elevated.

Management explained that the company secured a large tender, which led to a jump in inventory. Inventories rose from Rs. 675 crore in March 2025 to Rs. 1,178 crore in September 2025. This is expected to normalize over the next three months, which could reduce debt by around Rs. 300 to Rs. 400 crore. The increase in debt is linked to working capital needs due to rising copper prices and is largely non-fund based.

Reserves have also increased to Rs. 1,294 crore in September 2025 compared to Rs. 928 crore earlier. Cash flow from operations stood at Rs. 4 crore. Inventory days were at 38 days, and the cash conversion cycle stood at 39 days.

Expansion and Outlook

The Copper Anode segment is expected to start operations first, followed by phased commissioning of copper cathodes and downstream value-added products across FY26 and FY27. As the project scales up, capacities in anodes and cathodes will increase progressively. Commercial operations in wire rods, busbars, profiles and coating facilities will begin in a staggered manner.

This forward integration is expected to improve the product mix, strengthen customer relationships and support margin expansion over the medium term. Management has also stated in a recent interview that the company expects revenue growth in the range of 40 percent to 50 percent in FY27.

Future Growth Drivers

Industry Outlook

Jain Resource Recycling operates in a structurally strong industry supported by clear energy, cost and regulatory advantages that position recycling as a long-term growth driver. Aluminium recycling consumes up to 95 percent less energy than producing aluminium from virgin raw material, while recycling copper saves up to 85 percent of the energy used in primary production. Using secondary lead instead of ore reduces carbon dioxide emissions by 99 percent, and primary tin production requires 99 percent more energy than secondary production, highlighting the strong environmental case for recycled metals.

On the policy front, the government has introduced supportive measures such as the National Critical Mineral Mission Policy 2025, the Extended Producer Responsibility framework for non-ferrous metals 2024, the Vehicle Scrappage Policy 2021, the National Non-ferrous Metal Scrap Recycling Framework 2020, the National Resource Efficiency Policy 2019 and the Steel Scrap Recycling Policy 2019. Additionally, a mandate requires all new products made from non-ferrous metals to contain a minimum of 5 percent recycled content starting FY28, with copper recycled content expected to rise from 5 percent in FY28-29 to 20 percent by FY31-32, and aluminium from 5 percent to 10 percent over the same period, creating a strong structural demand tailwind for organized recyclers like Jain Resource Recycling.

Medium Term Growth Strategies

Jain Resource Recycling’s medium term growth strategy focuses on forward integration into copper value added products, expanding beyond recycling into the manufacturing of copper cathodes, wire rods and copper busbars. The company plans to use finished products from its recycling facilities as feedstock and undertake electrolytic refining to remove fringe metallic impurities, thereby producing high quality copper cathodes. These cathodes will subsequently be converted into high quality copper wire rods, strengthening its presence across the copper value chain and improving value realization.

The forward integration project is being executed through a wholly owned subsidiary, Jain Green Technologies Pvt Ltd. The company has acquired a suitable land parcel of 6.58 acres in SIPCOT Industrial Estate at Gummidipoondi for this expansion. The total capex plan for Phase I stands at Rs. 95 crore, to be entirely funded from internal accruals, of which Rs. 57 crore has already been spent till December 2025. The planned capacity for the facility is 9000 MTPA, positioning the company to scale up in higher margin copper products.

Construction progress as of December 2025 stands at approximately 80 percent. All critical machinery has been ordered, with deliveries expected to begin in the latter half of Q3 FY26 and Q4 FY26. The project is advancing as planned, with the anode phase expected to commission in Q4 FY26 and the cathode phase targeted for Q1 FY27. Additionally, the company plans to operate an in-house rooftop solar power plant to enable production of Green Copper Cathode, aligning the expansion with sustainability goals and enhancing its value proposition to customers.

Long Term Growth Strategy

Jain Resource Recycling’s long term growth strategy centers on expanding manufacturing capacity and diversifying operations through strategic entry into niche recycling verticals. The company is exploring new recycling domains to widen its product portfolio and deepen its presence in high value segments. A key part of this strategy is forming joint ventures with reputed scrapyard companies to set up recycling plants in India, strengthening sourcing linkages while expanding processing capabilities in an organized manner.

The board has considered and approved the proposal to acquire equity shares of Abraj Al Khaleej, Kuwait Company, under which the company will acquire a 25 percent stake. This investment will provide a platform to expand presence in the Middle East by leveraging the investee company’s established operations, local market knowledge and customer base. Additionally, the company has entered into a joint venture with C&Y Group Investments Inc. and incorporated Jain CY Circular Solutions Private Limited to set up a copper scrap recycling facility in Ahmedabad, reinforcing its forward integration and recycling capabilities.

Beyond metals, the company is targeting growth in emerging scrap segments such as automotive tyres, e-waste and solar panels. In automotive tyres, rising vehicle numbers are expected to increase tyre replacements, driving demand for recycled rubber and retreaded tyres across industries including road construction.

In e-waste, increasing use of smartphones, laptops and appliances is supporting scrap generation, enabling recovery of plastics, base and precious metals, stainless steel and rare earth minerals, with organized processing improving efficiency. In solar panels, the growing volume of end-of-life solar scrap is expected to enhance recovery of aluminium, glass, plastics, silver and rare earth metals, supported by India’s renewable energy push, ageing panels and rising sustainability focus among domestic companies.

Jain Resource Recycling appears to be positioning itself as a scaled and integrated player in India’s growing recycled metals ecosystem, with a strong focus on copper and value-added products. Its diversified sourcing network, export-oriented business model and forward integration into higher margin segments provide visibility for growth, while policy support and structural demand from energy transition and electrification create long-term tailwinds.

At the same time, investors should continue to monitor working capital intensity, debt levels and execution of expansion plans, which will be key to sustaining profitability as the business scales. Overall, if the company delivers on its capacity expansion and margin improvement plans, Jain Resource Recycling could evolve into a meaningful growth story within the non-ferrous recycling space over the coming years.

Disclaimer: The views and investment tips expressed by investment experts/broking houses/rating agencies on tradebrains.in are their own, and not that of the website or its management. Investing in equities poses a risk of financial losses. Investors must therefore exercise due caution while investing or trading in stocks. Trade Brains Technologies Private Limited or the author are not liable for any losses caused as a result of the decision based on this article. Please consult your investment advisor before investing.

The post Jain Resource Recycling Stock: Can the Company Lead the Copper Recycling Sector in FY27? appeared first on Trade Brains.